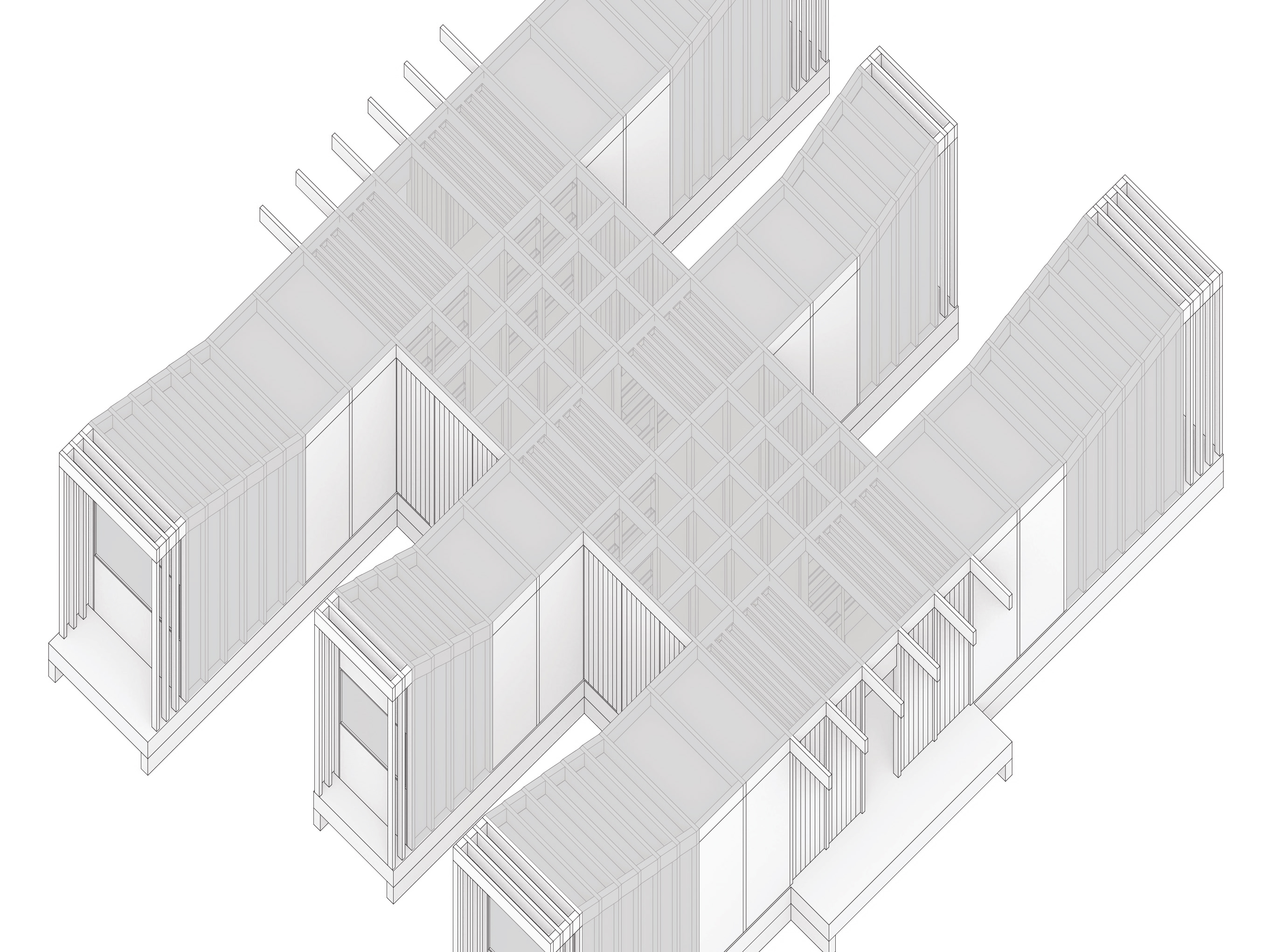

The project starts from the search for a design that challenges the structure of a tall building. With this in mind, the use of wood for some of its structural elements is proposed, since this material is not found in the most used on the market for the construction of large-scale towers, making it an opportunity for project exploration. Based on the study of the innovative CLT and Mass Timber technology, a hybrid structure is designed, where the columns, beams and habitable slabs of the building are made of wood and the vertical cores are made of reinforced concrete. Steel profiles are also used for a series of lattices that aim to stiffen the structure.

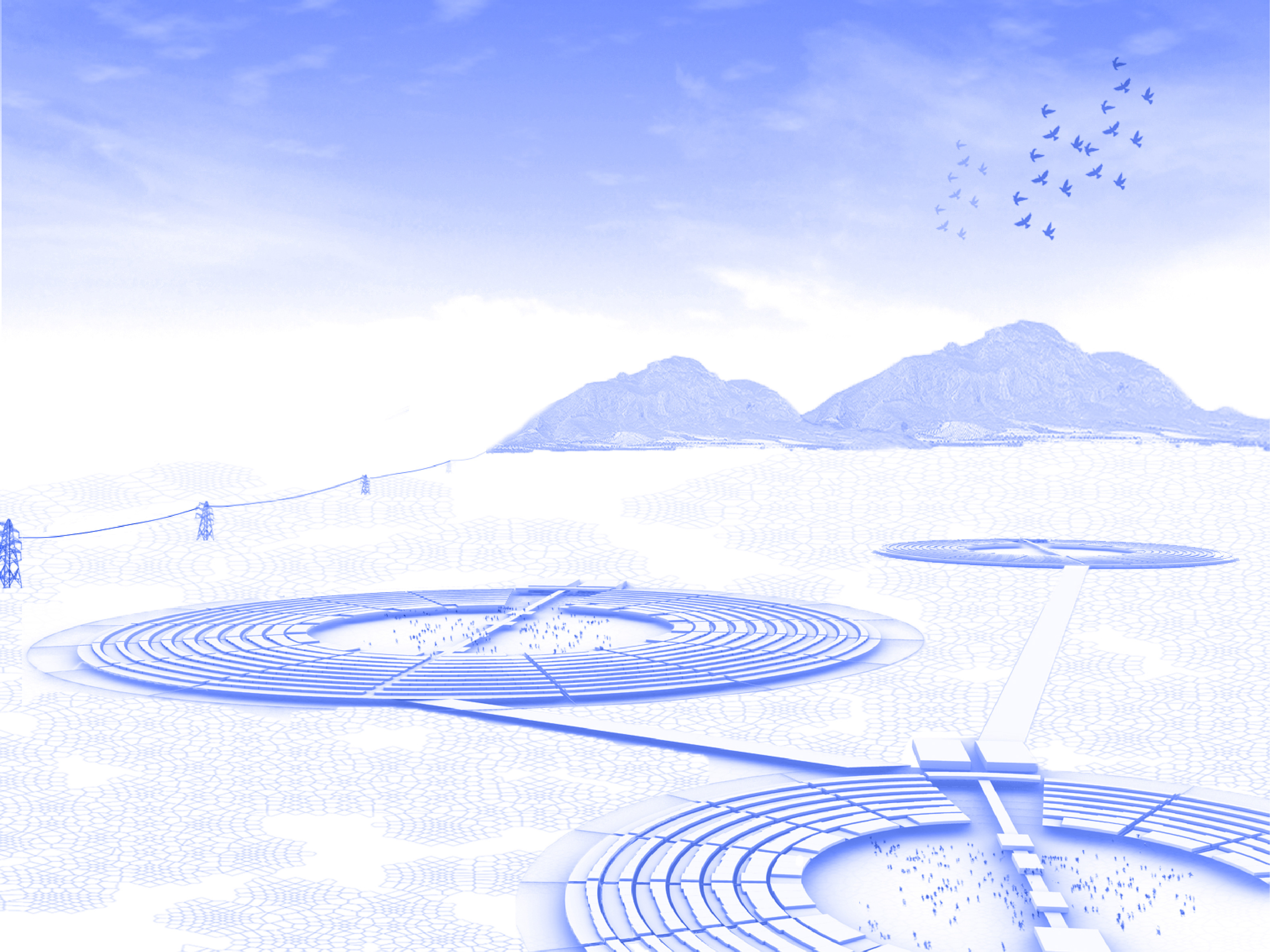

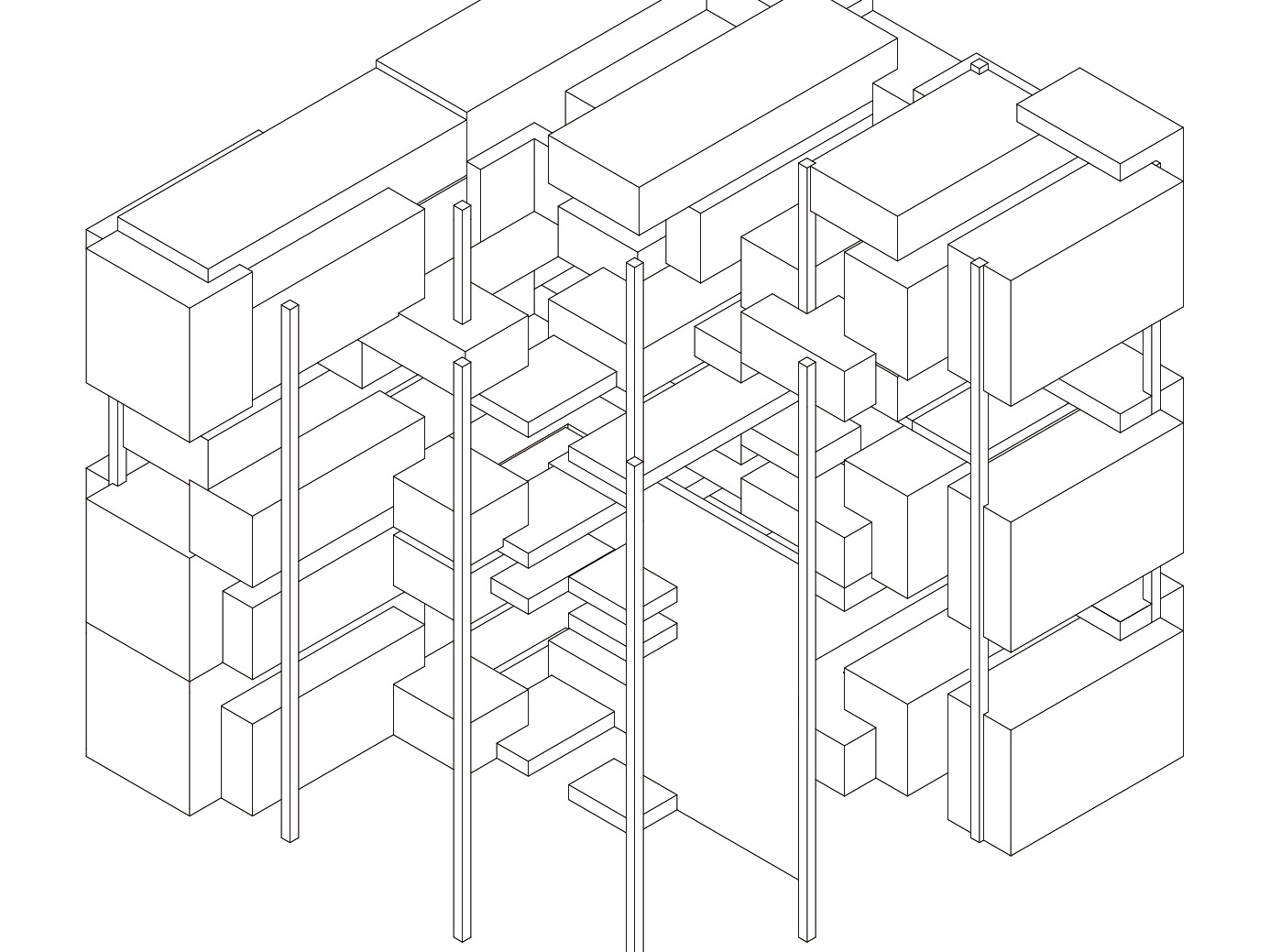

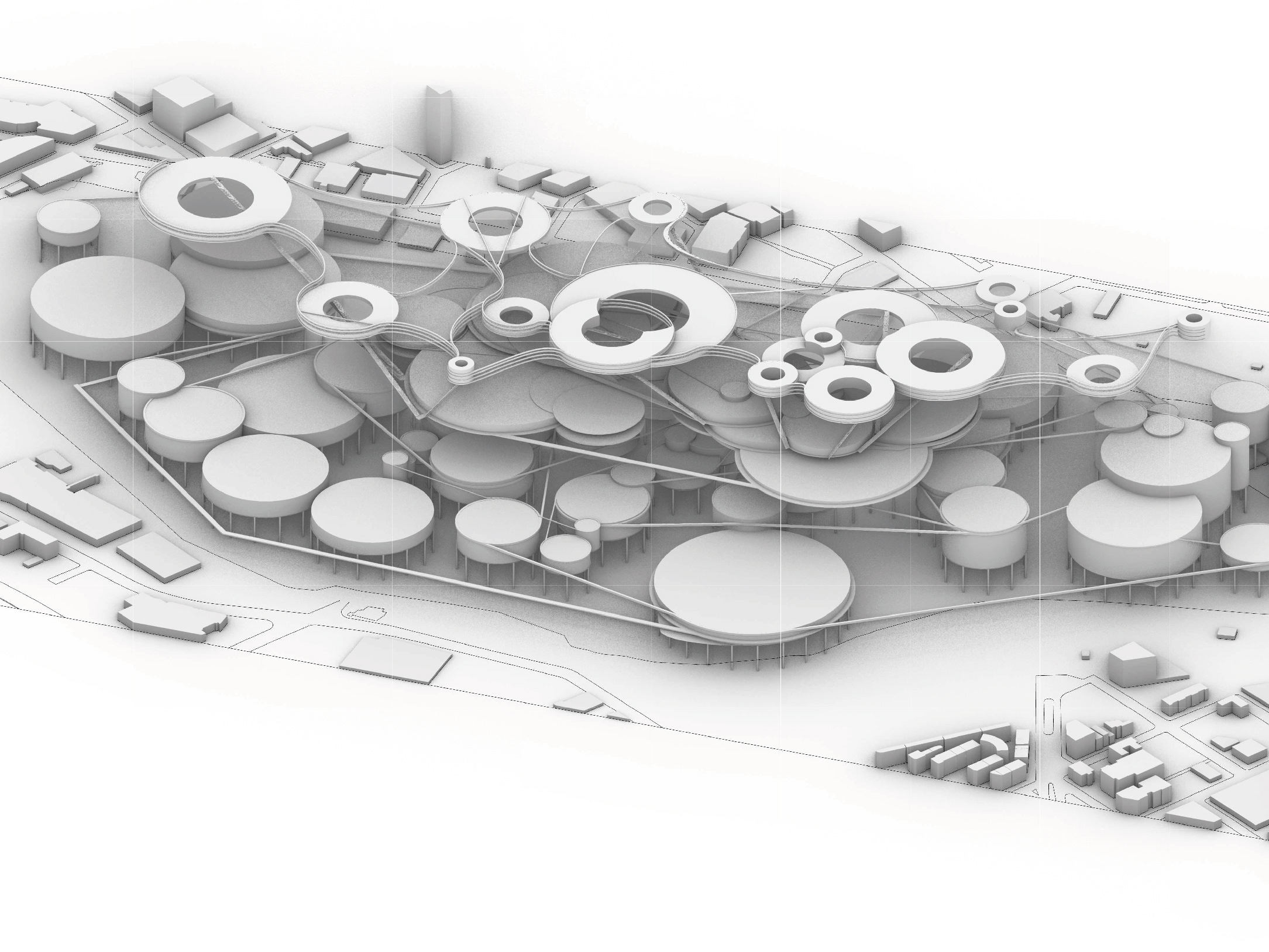

The use of wood in a high-rise building allows it to be given a lightness not only visual but also structural. This becomes key in relation to the earthquake loads that the tower can perceive, since being lighter, it is easier to resist the horizontal stress. In turn, this lightness contributes to less structural stress due to gravitational loads. The design then is made up of 5 “boxes” made up of a set of slabs reaching a total height of 245m. These, as you go up in height, rotate axially at 90° while they are offset from their central axis, generating the effect of appearing to be floating. Around these sets of slabs, 4 vertical concrete cores grow, which in addition to being structural, meet the objective of access and service to them.

These cores are also connected to each other by walkable horizontal bridges, below each “box”, which help to receive the loads by transmitting them, as well as to stiffen the cores. To take the challenge a little further, 15m span cantilevers are worked into the slabs. These allow that, together with the gap, a particular spatial perception is generated that appeals to the visuals both from interior to exterior and from exterior in its entirety.

CLT Technology - Mass Timber

The project explores the Mass timber technology, which allows the construction of high-rise buildings with solid wood as an alternative material to steel and concrete. This type of construction contains various systems: Cross-Laminated Timber (CLT), Nail-Laminated Timber (NLT) and Dowel-Laminated Timber (DLT) among others. The slabs are made up of CLT panels. This technology consists of several layers of wood glued together, forming a framework of slats, which are arranged perpendicularly. The panels used in the project have 5 layers, which complete a thickness of 0.17 m. In addition, the module of each panel is 19.5 m long and 3 m wide. This system can implement other materials besides wood to improve its structural efficiency. That is why a layer of concrete is added that takes the compressive stress.

Structural analysis

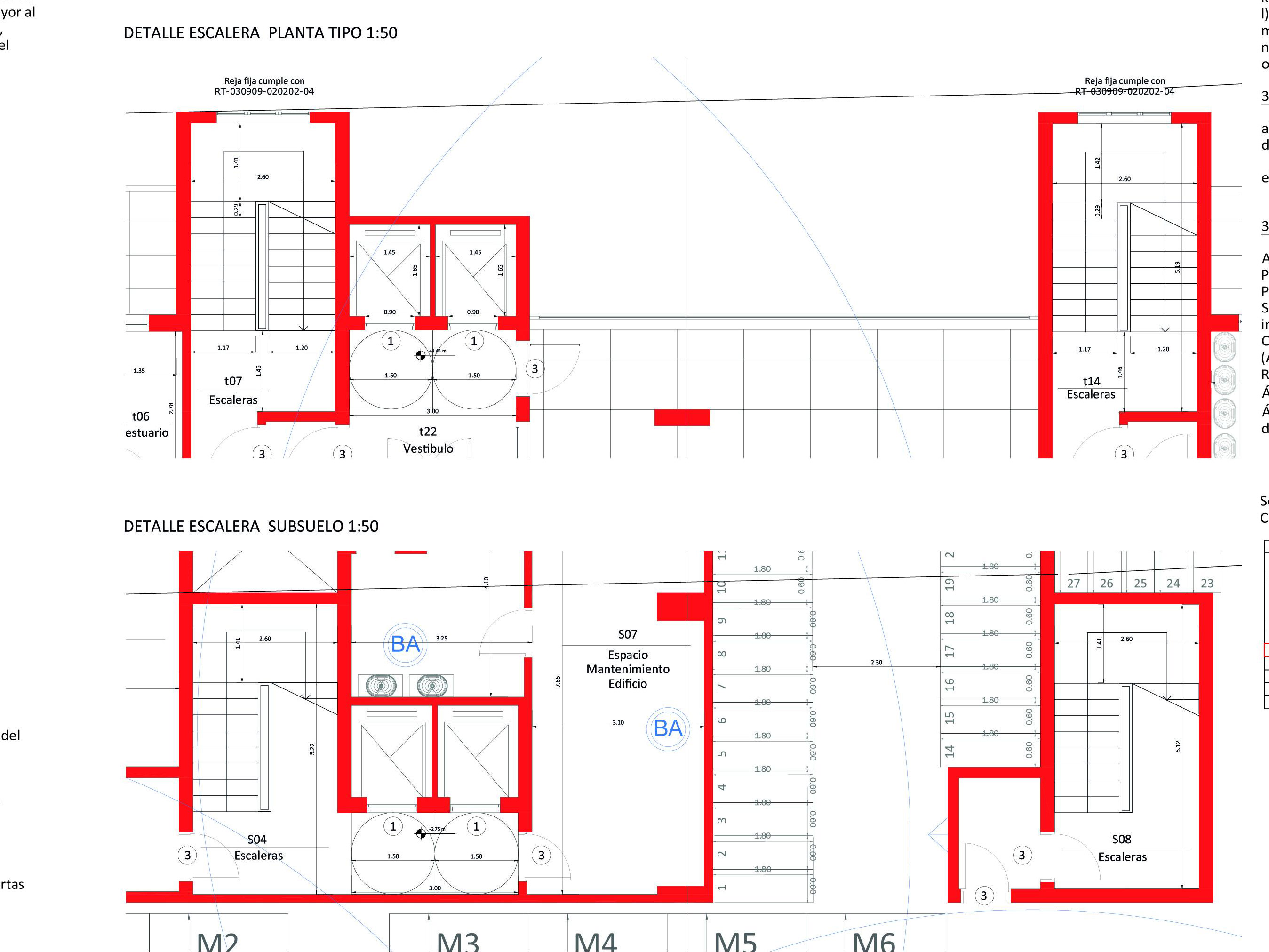

In a first instance, calculations are made that allow us to establish an approximate of the structural dimensions of the elements that make up the building. Regarding dimensions, the slabs of the ground floor set are square 45m x 45m. And the slabs of the other boxes, being rotated, have a rectangular configuration of 45 m x 37.5 m. All the slabs have an enclosure that retracts 2.5 m from their limit. The plant is configured around modules of 7.5 between columns -being the maximum allowed by the analyzed technology, which allows the office program to be adopted-. In turn, each set of boxes is supplied by only two of the cores, although the bridges allow connection to the remaining two. Timberbox has a total of 55 stories above the ground floor, reaching a height of 245 m. All the slabs have a height of 4m, except the slab on the ground floor (5m) and those of the bridges (8m) due to structural reasons.

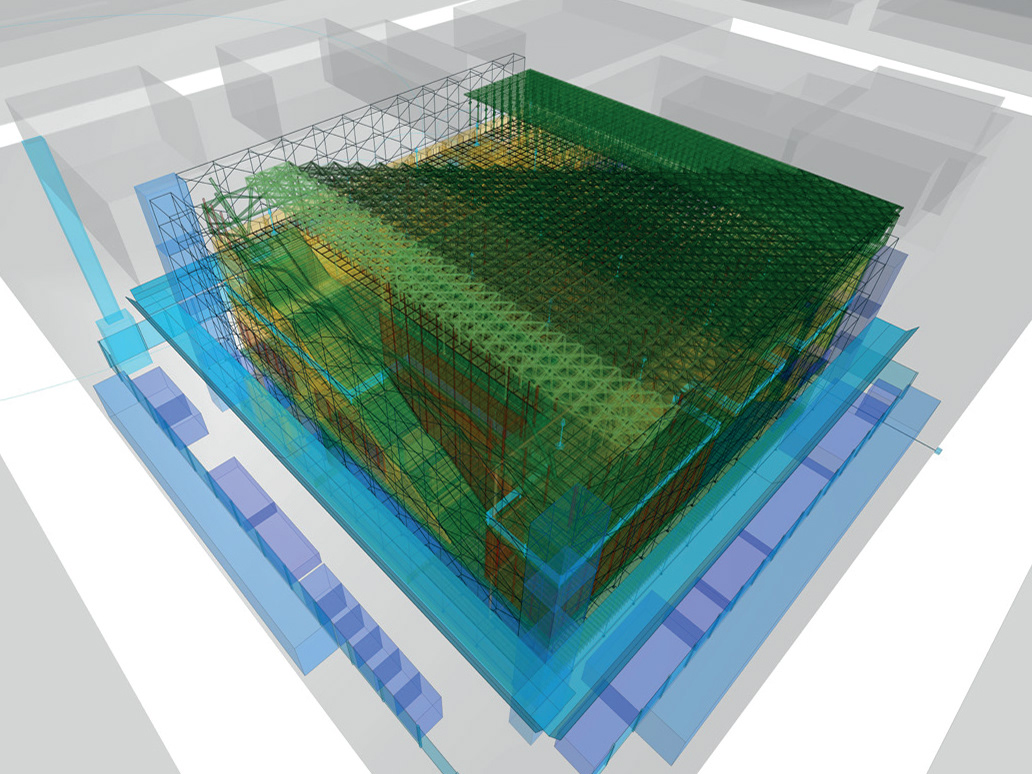

Robot and Karamba

Subsequently, the calculations are made through the incorporation of the project in Karamba and Robot. With respect to the CLT and Mass Timber technology, as it is a construction method that is not very standardized, research and projects already developed were used as guides for the work. Since these calculation programs have a very low level of specificity, we understand that their results are indicative. It is observed that the admissible deformation of the building as a whole (span/500) is 49cm, and that obtained by means of Karamba and Robot is less than 30cm, complying with the admissible deflection. This deformation increases at higher altitudes, due to the horizontal forces caused by the wind. The use of the building can be seen increased in the lower part of the cores, due to the transmission of loads accumulated in these points. The highest stresses are found in the cross-linked bridges. In a matter of the slab, the deformations in the z axis give a maximum of 0.6 cm. It is observed that the permissible deformation in the slab is 1.5cm (750/500). The allowable tension in the beams is 90 kg/cm2 and the result of the calculations in Robot is 35.86 kg/cm2.

As a conclusion, we find that the CLT is an innovative and interesting technology, which brings new structural challenges. Being a material with a low impact on the environment and due to its structural benefits, it is understood that this technology will be developed and will be more commonly used in the future. We believe that Timberbox's challenge was the development of a wooden structure in height, which made us go beyond the conventional and investigate this new field of construction.